We Design the Electronics, We Create Electronic Products, We Build Electronics Based Prototypes, We Develop the Apps and Cloud Architecture

We Are An Electronics Design, Software and Apps Company, Supporting Clients

- Develop Electronics Based Concepts & Products

- Provide R.T.O.S. and Microcontroller Customisation and Coding

- Make Working Electronics Based Prototypes

- Add Extra Functionality On Existing Products

- Reverse Engineer Existing Electronic Products

- Undertake Internet Of Things (I.O.T) Projects

- Design Apps and Cloud Server Applications

- Offer Full Consultancy and Advisory Services

We Design & Develop Electronics Based Products and Concepts

For over 10 years we have provided individuals and organisations with a complete electronic's design capability in which to develop their customised electronic products. Whether all or parts of these elements of the electronics design, prototype delivery, Apps and Cloud development, testing, certification and manufacture are required we have all the skills, experience and resources at hand to successfully undertake your project.

Concept To Prototype Design

We're focused on consulting, designing, developing and manufacturing customised electronic engineering and electro-mechanical solutions. As a globally connected organisation, we deliver state-of-the-art design and engineering solutions to organisations worldwide. This provides us with an extensive know-how in design, build and component selection.

Electronic Design Services

By combining our local, on-the-ground technical expertise with account management that in turn is fully integrated with our electronic engineering resources within the UK and India we believe we offer the

best of both worlds; comprehensive face-to-face customer support whilst deploying the most effective resources best suited to meet your needs.

Our Capabilities

- New Electronics Product Development

- Electronics Design Hardware, Firmware, Gerber's

- Firmware Development

- PCB Design

- Mechanical Design

- Electronic Prototyping

- Wireless Design

- Assembly and Manufacture

- Mobile Applications

- Cloud Server Applications

- Concept and Proof Of Concept Specifications

We Also Provide Tailored Electronics Design Services To Clients

When resource is required in aspects of electronic design our team can provide skills and resource in:

- Hardware design services including component selection, schematic design, PCB design and Gerber file generation

- Bespoke Microcontroller and Embedded System firmware coding and provision .

- Real -time Operating System (RTOS) customisation based on clients requirements

- Manufacturing analysis including Bill of Materials (BOM) and volume production costs.

- Android and iOS application development

- Server application development and Database management

- Design, development and Support of Internet of Things (IOT) and associated Cloud architecture

- Device testing and Certification support and if required CE Marking

Latest Client Product -Smart Door

Latest Products

Superhailer -deployed worldwide. Electronics and connectivity. https://www.superhailer.com/

Electronics Intellectual Property

Whether it is for the design of a particular component integration or for an entire product we provide a full documentation blueprint pack including the electronics hardware design, PCB layouts and firmware ensuring that all intellectual property created, as part of the project, is retained by the client.

Electronics Product Design Initial Evaluation

We provide free advice and quotations for clients from a given specification where we estimate the engineering hours, timescales and associated costs and where needed likely manufacturing unit costs.

A Typical Electronics Product Design Process

Depending on the complexity of a particular project we recommend that after the initial review we undertake a Requirement Specification where we document all of the desired features, functionalities and mechanical constraints of the required design and provide an accurate unit Bill of Materials (BOM) on which to base actual manufacturing appraisals.

Once the design has been frozen within the Requirement Specification we undertake the Hardware design, the PCB layout, the Firmware and if required Apps and Cloud server works. If enclosures are required we can 3D Cad design these and 3D print, Vac cast or SLA dependent on the needed enclosure properties required.

From these designs we then manufacture the electronics prototype hardware PCB, load the firmware and test/debug the electronics and if present apps and cloud integration.

We then deliver the working electronics prototype for customer testing and remote upload any firmware releases alongside the full Blueprint Documentation.

Electronics Prototype to Manufacture

Clients at this stage can take their prototype and Blueprints to third party Electronic Manufacturing companies or undertake with Ricco Manufacturing.

At this stage we would normally undertake a full manufacturing analysis of the product checking component supply, component alternatives, potential reductions in manufacturing cost covering all aspects of the product to optimise the production run.

We then undertake testing and any necessary Certification of the design to meet with the conformity’s of the Market in which they are intended for.

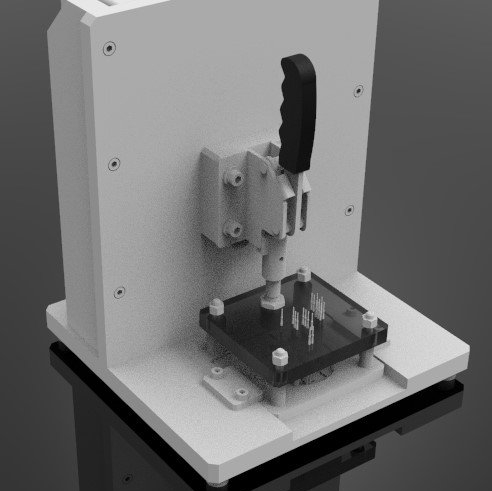

Dependent on the volumes envisaged we design a Test Jig in order to automate the testing of each unit off the production line and load any firmware.

We have several local Electronics Product Manufacturing sites and dependent on the needs of the client we can then manage the entire product runs including packaging and shipment